Background

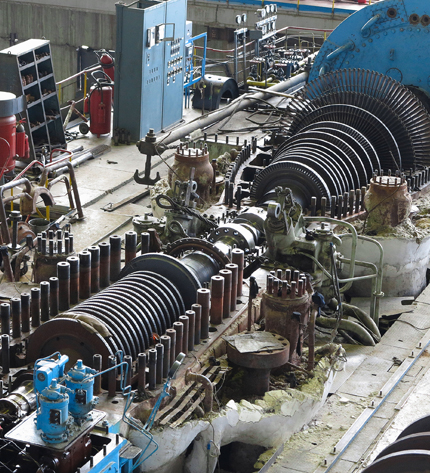

Tata Power is the largest power generation company in India aimed at providing uninterrupted power supply from its various plants located across India. In their Maharashtra plant they needed to preserve 6 Steam Turbines of 500MW capacity each for a minimum of 6 months idle period in humid conditions. Since moisture effect can corrode IP and LP side (Area) of the turbine, both IP Turbine (Ø3.3 mtr x Length 3.4 mtr) and LPTurbine (Ø6.0 mtr x Length 8.0 mtr) needed to be protected from moisture,

Problems

Rate of corrosion accelerates when Relative Humidity crosses the critical level of 35%. Since it was monsoon season, the ambient RH was above 80% and temperature was approx. 30oC. Due to moist ambient conditions, IP and LP turbine sides can start getting corroded during idle period which may lead to deterioration & decrease in the life of the parts and components and failure of the turbine in the long run.

Our Solution

Dehumidifier was installed near the turbines. From the process inlet of the dehumidifier ambient air was taken in and from the process outlet of the dehumidifier, dry dehumidified moisture free air was supplied into the turbine. Dry air ensured that the turbine is under optimum preservation condition by controlling moisture and humidity during idle time.

The complete preservation service provided peace of mind to the client. The installed system worked perfectly with very pleasing results.

Benefits

- Dehumidified moisture free air ensured no rust development or corrosion of the turbine

- It prolonged the life of the turbines